|

|

- Introduction of Research Group

Department: Mechanical Engineering

Area: Complex Mechanics Area

Subarea: Solid Mechanics Field

Research Group Objective:

Modeling of Multiscale Solid Mechanical Behaviors and Designing of Novel

Structures

Topics:

- Nanoplasticity by Nanoindentation and Collective Defect Mecahnics

- Defect Mechanics of Bulk Metallic Glasses

(http://glasmet.imr.tohoku.ac.jp/) (http://glasmet.imr.tohoku.ac.jp/)

- Thin Film Growth Modeling

- Designing and Testing of Nanostrucutres by FIB-CVD

- Nondestructuve Mesoscopic Observation by New Microscopy

: Scanning Electron-induced Acoustic Microscpoy (SEAM) : Scanning Electron-induced Acoustic Microscpoy (SEAM)

- Dental Occlusive Mechanics for Oral Engineering

1, Abstract 1, Abstract

We research the solid mechanics field where much attention is paid to

the multi-scale modeling and analyses. In order to link the hierarchical

solid mechanics phenomena together, our research field ranges from the

first principle calculation (ab-initio calculations) to get the electronic

states information under the external loading, the mezoscopic simulations

which represent the collective mechanical behavior of defects like the

dislocation and the macroscopic elastic-plastic finite element simulations. We research the solid mechanics field where much attention is paid to

the multi-scale modeling and analyses. In order to link the hierarchical

solid mechanics phenomena together, our research field ranges from the

first principle calculation (ab-initio calculations) to get the electronic

states information under the external loading, the mezoscopic simulations

which represent the collective mechanical behavior of defects like the

dislocation and the macroscopic elastic-plastic finite element simulations.

Moreover, we have been put much efforts to perform the noteworthy experiments

and to develop the new experimental technique as well. The former is concerning

the nano-indentation, the in-situ observation of the mechanical testing.

The latter is related to the focus ion beam (FIB) applied technique and

the new scanning electron-induced acoustic microscopy (SEAM). Moreover, we have been put much efforts to perform the noteworthy experiments

and to develop the new experimental technique as well. The former is concerning

the nano-indentation, the in-situ observation of the mechanical testing.

The latter is related to the focus ion beam (FIB) applied technique and

the new scanning electron-induced acoustic microscopy (SEAM).

We have also been collaborating to the dentists. Developing the three-dimensional

finite element analyses of the occlusive force and moment balance, our

numerical analysis information is coupled with the dental treatments. We

aim to build up the ideal occlusive master curved surface from the mechanics

standpoint. We have also been collaborating to the dentists. Developing the three-dimensional

finite element analyses of the occlusive force and moment balance, our

numerical analysis information is coupled with the dental treatments. We

aim to build up the ideal occlusive master curved surface from the mechanics

standpoint.

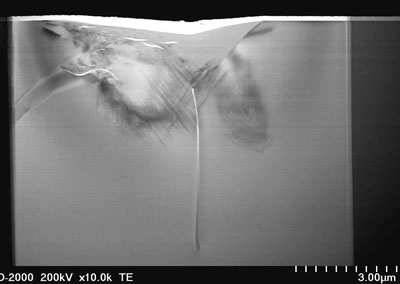

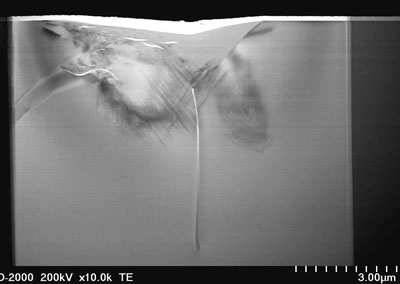

Fig.1 Dislocation network observation under nano-indentation of

single crystal silicon or aluminum.

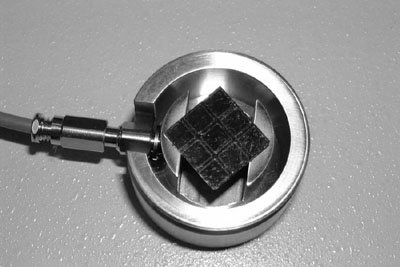

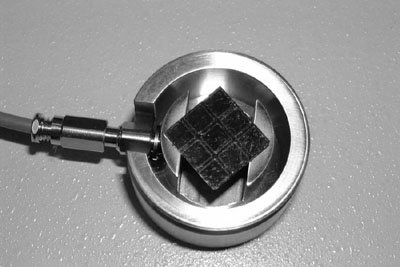

Fig.2 The holder putting the sample of a transistor tip.

2, Main Research Theme 2, Main Research Theme

- (Cellular Automata (CA)+Crystal Plasticity) Combined Scheme,

3-Dimensional CA Discrete Dislocation Method (3D CA-DD), Dislocation

Collective Behavior, Molecular Dynamics (MD)

- Cluster Structure, 0(N) Tight-binding MD (TB-MD), Diamond-Like-Carbon

(DLC), Carbon Nanotube, Ab-initia Calculation

- Scanning Electron Beam-indeed Acoustic Microscopy (SEAM), Dislocation

Network, Non-destructive Observation, Nano-indentation, Silicon, Phase

transition and Dislocation Network

- Occlusion Mechanics, Dental Implant Design, FEM Simulation

3, The Handai (Osaka University is called the "Handai") FRC 3, The Handai (Osaka University is called the "Handai") FRC

We participate in one of the Handai FRC projects "Concurrent first

principle computational system for structural integrity of nanostructured

materials". We participate in one of the Handai FRC projects "Concurrent first

principle computational system for structural integrity of nanostructured

materials".

Improving the first principle calculations for practical multinary compounds and non-periodic structures containing some defects, new computational mechanics system with multiscalability has been developed. It can evaluate the material properties of nanostructured materials and also trace dynamics of mechanical structures assembled on nano-scale. The focus ion beam technology is available to innovate the nanostructures. which should be integrated from the nanoengineering view points by the newly developed concurrent computationalmechanics system. Improving the first principle calculations for practical multinary compounds and non-periodic structures containing some defects, new computational mechanics system with multiscalability has been developed. It can evaluate the material properties of nanostructured materials and also trace dynamics of mechanical structures assembled on nano-scale. The focus ion beam technology is available to innovate the nanostructures. which should be integrated from the nanoengineering view points by the newly developed concurrent computationalmechanics system.

LINK >>> Project Introduction (PDF 2.04MB) Project Introduction (PDF 2.04MB)

|

|